What is the battery module, cell and pack?

What is battery module?

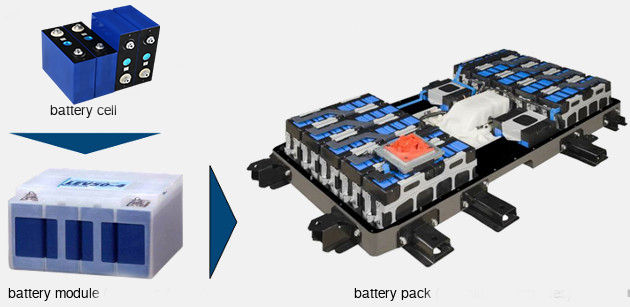

When it comes to battery modules, people often think of two other terms: Battery cell and Battery pack. In fact, “battery” is a generic term for all three, while “battery cell”, “battery module” and “battery pack” are different forms of batteries in different stages of application. The smallest of these units is the battery cell, multiple cells can form a module, multiple modules can form a battery pack by adding BMS and other management systems. Therefore, we can understand the battery module as an intermediate between the battery cell and the battery pack. When several battery cells are packed in a common housing frame and connected to the outside by a uniform boundary, it is a battery module. It consists of a series-parallel combination of cells whose structure has the task of supporting, fixing and protecting the cells. The criteria for assessing the merits of a battery module are whether it is able to fix the position of the cell and protect it from performance-damaging deformations, how it fulfills the temperature control of the cell, etc…

The lithium battery modules that are currently on the market are mostly modules for electric vehicles. Many lithium battery manufacturers will launch some fixed parameters of the module products according to the needs of the market, also known as standard module. If the standard module cannot meet the needs of customers, it is necessary to customise the lithium battery module to meet different needs, also known as custom battery module.

Through the above, we have a general understanding of the battery module. Here we will introduce battery modules in more detail by comparing battery cells, battery packs and the process of pack formation.

Battery module vs cell

As the smallest unit of the battery cell, its performance directly affects the performance of the battery module. Therefore, selecting the right battery cell is the first step in assembling a battery pack. Battery cells are usually formed according to the “barrel principle”, i.e. the cell with the lowest capacity in a group of cells determines the capacity of the entire group of batteries. This assumes that the selected cell type, model consistency, capacity, internal resistance and voltage difference do not exceed 2 %.

Li-ion battery cells can be divided into soft packs, cylindrical cells and square cells: depending on their structure.

| Soft pack | cylindrical | square | |

| Advantages |

The external structure has small effect on the cell, the material used for the packaging has a low mass and the energy density of the battery is high. |

High process maturity, mature shell structure, low process manufacturing cost. |

High protection for the cell, can ensure the explicit conduction of internal heat by reducing the thickness of the single cell, and the safety performance of the cell is greatly improved. High capacity of single cells, less cells required for battery pack. |

| Disadvantages |

The sealing process of large capacity batteries is more difficult and relatively unreliable, and the mechanical strength of the aluminium-plastic composite film used is low, and the life of the aluminium-plastic composite film limits the life of the battery. |

Uneven distribution of current density on the collector, resulting in an uneven reaction of the individual internal parts. The heat generated in the battery cell is difficult to dissipate quickly and the accumulation poses a safety risk to the battery. |

Complex internal structure, high demands on the production process. The energy density of the cells was low in the early days, and in recent years there has been a major breakthrough in this area. |

Formation process

After the battery cells, we now turn to the connection of the battery cells. Currently, there are two main types of assembly methods: Bolting on and welding on:

| bolt-on | weld-on | |

| Advantages |

1. Simple and easy connection, low cost 2. Easy to assemble and disassemble, convenient for maintenance |

1. Good consistency and low contact resistance. 2. The contact resistance is stable because the contact surface is closed and not easily oxidized. |

| Disadvantages |

1. Surface is prone to corrosion. 2. Influenced by preload force, surface quality, unstable contact resistance |

High equipment cost and high initial investment. |

As a battery module of an electric vehicle, it must be constantly exposed to shocks and vibrations. From the advantages and disadvantages of the above connection methods, it is clear that using screws to connect the battery cells leads to hidden problems during use. Therefore, with the availability of laser welding equipment, the second connection method is mostly used nowadays. Or you can buy and use the battery modules directly.

Battery module vs pack

As already mentioned, a battery pack can consist of several modules and a management system such as the BMS. Some may now ask, why not just use the cells for the battery pack? This provides more space to increase capacity and improve range. For some small battery packs (e.g., 12 V 100 Ah energy storage battery pack, etc.), we can indeed do this, not only to reduce the weight but also the size. But in electric vehicle battery, energy, volume and weight as well as cost and safety must be considered. Electric vehicle batteries have a very high voltage and require many more cells, usually from a bundle of cells connected in series. If one cell has a problem, the entire battery becomes unusable, and it is troublesome to replace the cell in this case. It is also difficult to fix these cells so that they can withstand the vibrations in the car.

The cells form a module that is modularized and standardized. This is nothing more than a small loss of capacity and range. It not only improves the overall structural strength, but also improves the efficiency of heat dissipation, reduces the risk of thermal runaway, facilitates the later replacement of individual cells, and has a high conductor utilization in the later stage. It ensures later use and maintenance. Thus, the importance of the module lies in the minimum fault unit and modular structure at the platform level. Standardized modules, mainly to facilitate the advantages of both standardized production and installation and fastening. Adopt modular production, easy to weld, module transportation, improve production efficiency, improve the structural strength between cells, and good anti-vibration performance. This is also the reason why most car companies choose to use battery modules at present.

Leave a reply